Journal #1

Research Goals and General Goals:

- Find an Expert Advisor to mentor my project

- Research Polymer Basics

- Find Credible sources for information

- Research Polymerization processes and the different processes to produce polymers

- Research Polymer structure and nomenclature

My Research:

To start these weeks, I had one goal that desperately needed to be completed: finding an expert advisor. For a great majority of the first half of this period, I had taken up my time researching on various university professors who had experience with polymer science. These professors varied from having a B.S. in materials engineering to PhDs in Chemical Engineering. In order, I had sent a request to a Cal Poly Materials Engineering professor, two Georgia Tech Chemical Engineers, and a CU Boulder Chemical Engineering Professor. In the end, I was able to reach out a gain the mentorship from Christopher J. Hansen, a Chemical Engineering professor at the University of Massachusetts Lowell who has a PhD in Materials Science and Engineering. His expertise in the advanced manufacturing of polymers will indeed become handy in helping shape my project to reach the scales I wish it to be able to.

Meanwhile, I started conducting research from the very basics—what is a polymer? I needed a good basis to start gaining a general idea for what I was going to put myself through. To start, I watched some initial videos that had explained many of the basics. The first video I had reviewed over was all about the polymerization process of polymers. The process can be separated into Addition/Chain Growth Polymerization and Step Growth/Condensation Polymerization. We are going to focus solely on Addition/Chain Growth Polymerization for this project:

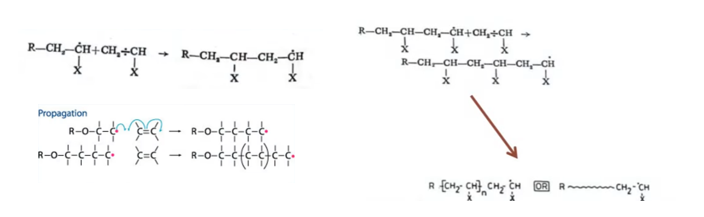

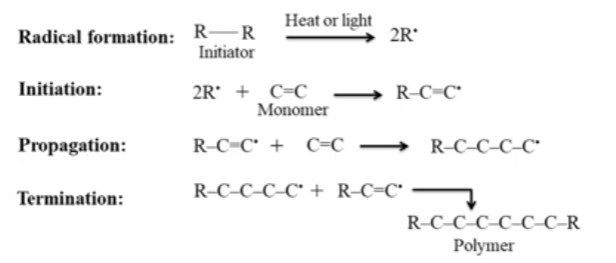

An addition or chain growth polymerization is defined as the process in which a polymer forms by linking monomers without the co-generation of other products, adding new monomer units to the growing polymer molecule one at a time through double or triple bonds in the monomers. Compounds that contain reactive double bonds undergo a chain polymer reaction. The most common mechanism that exists in the process is free-radical polymerization. Initiation of this mechanism begins at the decomposition of compounds known as initiators. The decomposition creates what is known as a free radical, a molecule that’s unstable but exists on its own. The process can be induced by light energy, heat energy, or by a catalyst.

The initiation process begins when the free-radical R attacks the double bond in the monomer molecule. This free radical interferes with one of the pi electrons and forms a normal pair of electrons. The leftover electron is sent to the other end of the molecule. This process must be extremely exothermic, producing a great amount of heat during the reaction.

Free-Radical Reaction Initiation Full Reaction

The next step is propagation, which begins when the radical site at the first monomer unit attacks the double bond of a fresh monomer molecule. This results in the linking up of the second monomer unit to the first and transfer of the radical site from the first monomer unit to second by the unpaired electron transfer process.

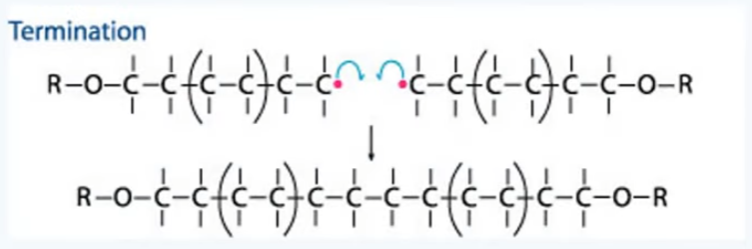

Finally, the polymer would go about termination, which can either be done by coupling, by chain transfer, or by inhibitors. For the process by coupling, at any given time, there may be quite a few growing chains present in the system. There exists a statistical probability of the two growing chains coming close to collide with each other. The process depends on factors such as time, temperature, monomer concentration, and initiator concentration. Two of these chains will end up colliding with one another to terminate the process and produce a finished polymer chain.

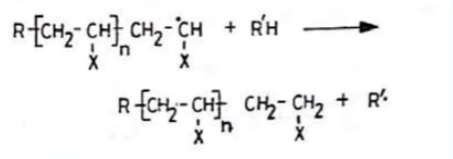

For termination by chain transfer, the growth of one polymer chain is stopped or arrested, forming a dead polymer. A chain transfer agent is present, which is also called a modifier or regulator, and has one weak chemical bond. These compounds react with the free-radical site of a growing polymer chain and interrupt chain growth, in the process of chain transfer, the radical is temporarily transferred to the regulating agent which reinitiates growth by transferring the radical to another polymer chain. Many modifiers are added to maintain certain mechanical properties.

For termination by inhibitors, chemical substances that can inhibit or kill the chain growth are added during the synthesis. Examples like oxygen are good inhibitors, explaining why many of these reactions occur in a nitrogen atmosphere. These can be added early on to limit polymerization.

To summarize the processes, I discovered a model showing polymerization from start to finish:

Source:

"Polymerization Process | Addition and Condensation | Mechanism Explained | TexConnect." YouTube, uploaded by TexConnect, 10 May 2021, www.youtube.com/watch?v=rG1qDXuRRoE&list=PLzmzvD7WyFMkAfNGtHB-oTaa0h7j4XxVc&index=1.

Accomplishments:

- Found an expert advisor to mentor over my project

- Explored the processes behind polymerization

- Narrowed the focus of my project to rudimentary polymerization

Reflections on Goals and Timeline:

While this research has me directed on the path I want to follow for this project, my inability to find a mentor for a great majority of the time had significantly flawed my timeline. To get back on track, I will be having to make some cuts to what I originally had planned for this project, which may include the YouTube channel I had been wanting to start before entering the class. This way, I can focus solely on getting a great product produced and worry about all of the flair of the project afterwards.